Baldwin & Francis undertakes a major heavy materials handling project to replace ageing Switchgear at a Lime works plant. We designed and manufactured bespoke switchgear panels to meet the complex and challenging installation requirements for L’Hoist Lime works.

L’Hoist are a global leader in lime, dolime and minerals, headquartered in Belgium they employ 6,400 employees worldwide. Lime has been produced at L’Hoist UK quarries for generations, with product purity being the reason for its longstanding success.

The L’Hoist plant located in Nottinghamshire, UK took the decision to replace their ageing switchgear which was reaching the end of its life cycle. The decision was both a safety and economic decision, but equally the performance considerations and reliability were vitally important aspects to L’Hoist who selected Baldwin and Francis for its high-quality Switchgear and services.

Baldwin and Francis worked with the L’Hoist team to provide considerable pre-order technical advice and onsite support to ensure that every fine detail was meticulously planned, ensuring there was no risk to the plant as it was critical that site operations were maintained without any disruption to their production during the installation.

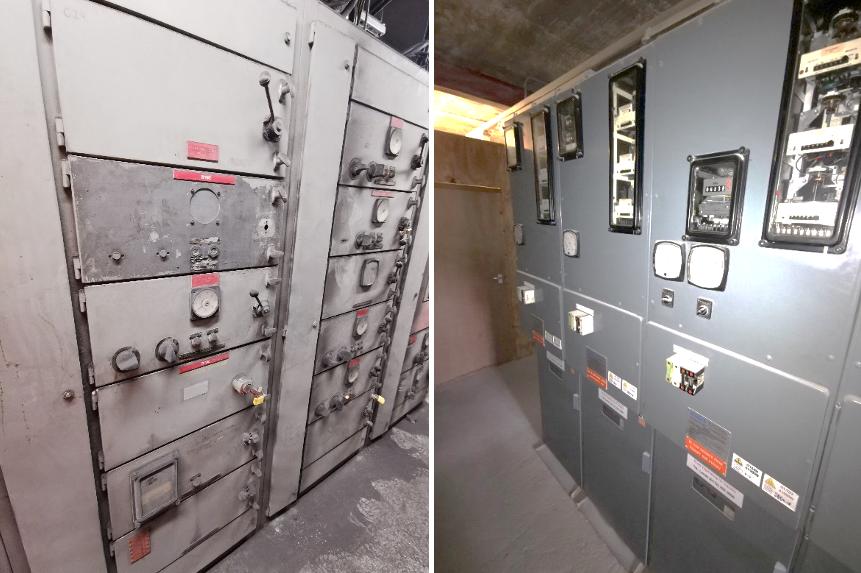

The Old Switchgear to be replaced with new B&F panels

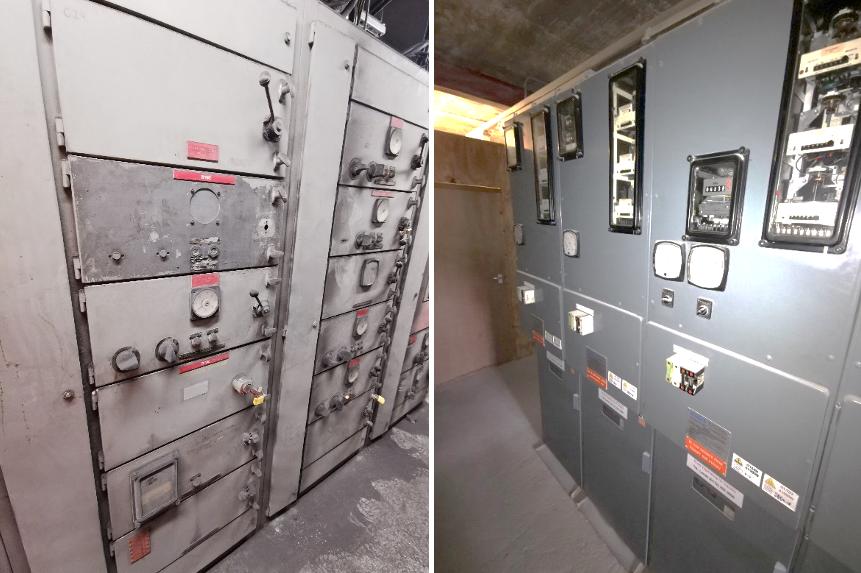

A new Medium Voltage (MV) Switchboard from the B&F Multivac Range (MV 11kV 25kA incomer and transformer outgoing) was designed to meet the IEC 62271-200 standards for long lasting, reliable performance, ease of handling and simplified maintenance. The bespoke design includes front and rear access and provides the ultimate level of safety with robust construction. B&F replaced all switchboards on the site without changing cabling arrangements, which also included DOL (Direct on-line) and Variable frequency drive (VFD) feeders. Space constraints presented a significant challenge for the B&F in-house design team, the design had to be very compact, and the equipment consolidated into one switchboard to fit in such a tight footprint.

Following this B&F manufactured and installed a new low voltage (LV) motor control centre (MCC) centralising control of all the motors onsite into one location, again ensuring the site remained operational throughout the installation process.

Sandy Walker of L’Hoist, lead engineer on this project, explained the team are very impressed with the build quality of the Switchgear and praised the high level of pre-order support which was the highlight of working with Baldwin & Francis.

The new LV & MV Equipment designed and manufactured at Baldwin & Francis’ Sheffield Headquarters

Baldwin & Francis Ltd design, manufacture and install LV and MV switchgear to customers worldwide, with a wealth of experience, technical expertise and engineering excellence, its success stems from its strong heritage and unrivalled support to all its customers worldwide.

From concept-design through to commissioning and aftersales support, Baldwin & Francis can assist in providing a tailored solution that meets your material handling needs. Please contact us for more information on 0114 286 6000 and ask for one of our dedicated Sales representatives who will be happy to support you.

Baldwin & Francis is part of the iDESo Group, headquartered in Sheffield, the iDESo group are the leading specialist in the manufacture of electrical switchgear and intelligent distributed energy solutions.