Deep within the snowy landscapes of Norway, six hours away from the bustling centre, lies a dormant coal mine that needed to be brought back into production. The task at hand required our century-long expertise in delivering high quality, custom-engineered solutions for the most daunting environments. Our mission: to inspect the mine’s critical CHP-style load centres and pave the way for their revival.

Join us as we recount our daring expedition through brutal sub-zero temperatures and unveil a ground-breaking solution that benefits clients far beyond the frosty tundra.

Setting the Scene

About 12 years ago, Baldwin & Francis left its mark on the Svalbard archipelago in the Arctic Circle, installing equipment for our esteemed client, Store Norske. Back then, the mine enjoyed government sponsorship, but unfortunately, the project met an untimely end. However, recent developments spurred a change of heart, prompting the decision to breathe life into the dormant mine once again.

This rekindling of coal production mirrors similar occurrences worldwide as countries scramble to reduce reliance on Russian energy supplies in the aftermath of the Russian war in Ukraine. From Germany’s reactivation of mothballed coal mines through the passing of emergency legislation to Greece, extending the operation of existing coal-fired power plants until 2028, the need for alternative energy sources has never been more evident. Even the UK is opening its first coal mine in three decades in Cumbria, solely to fuel steel production, highlighting the nation’s heavy reliance on Russian coal.

Why the Inspection Was Crucial

Load centres serve as the lifeblood of a coal mine, controlling vital components such as pumps, fans, hydraulics, and conveyor belts. Without these crucial systems, the mine would be unable to function. However, before coal production could recommence, thorough inspections, assessments, and testing of the equipment were necessary to ensure electronic safety and mechanical functionality. Tackling this arduous task was our trusted expert engineer, Shiji Krishan. With over 17 years of mining experience at Baldwin & Francis and a passport full of global projects, Shiji embarked on a ten-day endeavour like no other.

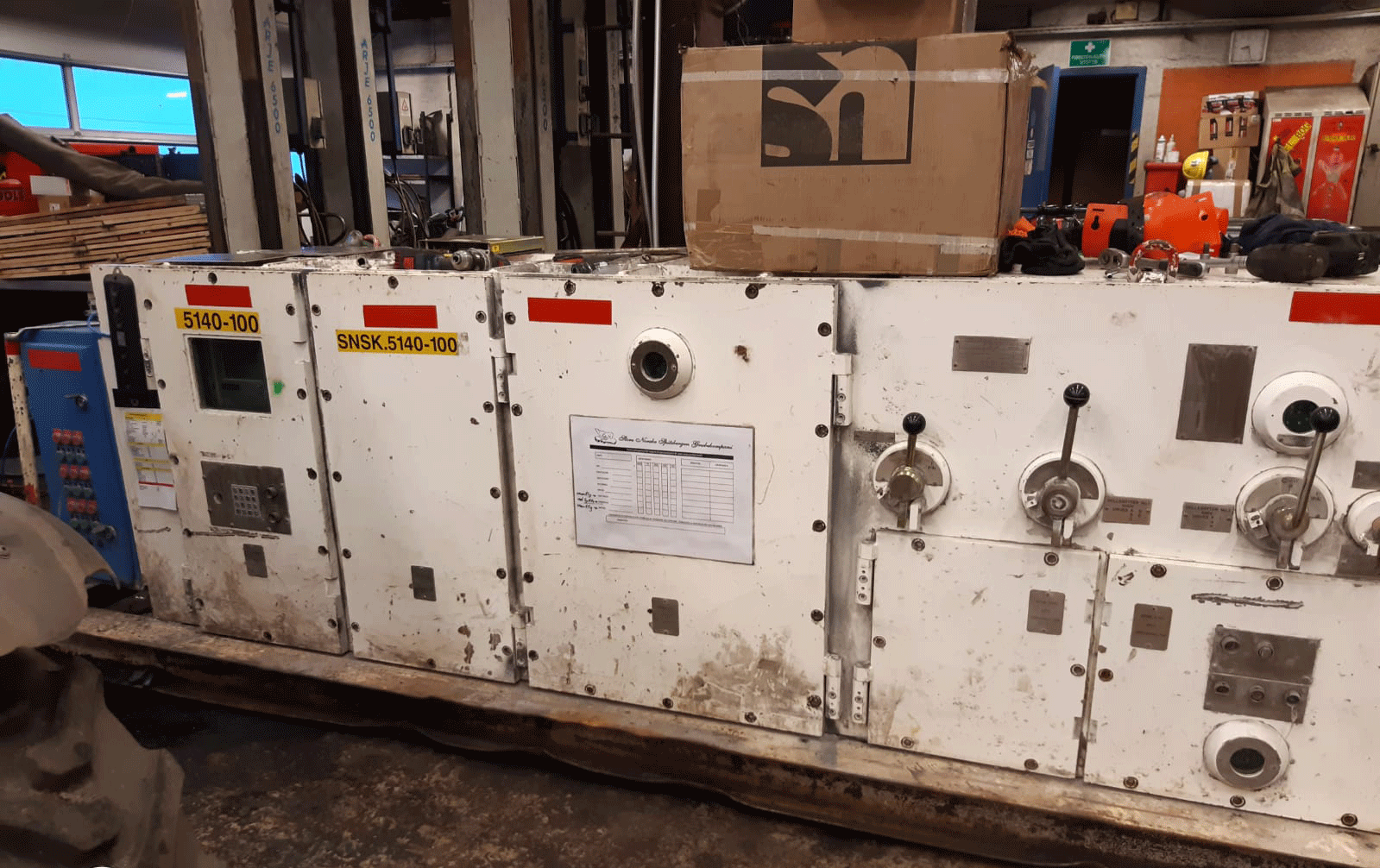

Load centre refurbishment for the Norway mines

Overcoming Unprecedented Challenges

Our path was not without its share of hurdles. The first challenge lay in the significant time gap between the mine’s operational period and our 2023 assessment, which spanned several years. During this hiatus, the mine fell vulnerable to flooding, subjecting external load centre components such as plugs, switches and sockets, to corrosive forces. While our load centres are classified as zoned equipment, suitable for use in gaseous atmospheres, they are not designed for water immersion.

The second challenge, undoubtedly formidable, was the unforgiving local weather. At night, in winter, Svalbard’s temperature plummets to as low as a bone-numbing minus 15 degrees Celsius. Inside the mine, Shiji braved a relatively warmer but still frosty five degrees, while outside, the mercury could easily dip to minus ten or more during his journey back to the hotel. Such frigid conditions demand specially heated electrical cables to ensure an uninterrupted power supply. Compounded by Shiji’s recent work in scorching Indian conditions, we made sure he had ample rest breaks to recuperate, bundled up in multiple layers to stave off the bitter cold. Undeterred by the adversities, Shiji tirelessly completed the service overhaul, meticulously inspecting the load centres for internal water damage, guaranteeing a flawless performance that would ensure successful recommissioning of the mine.

Delivering Game-Changing Efficiency

Initially, the mine boasted six CHP-style load centres. However, when the mine was mothballed years ago, four of these centres found new homes. Consequently, we inspected only two load centres on-site in Norway, while the others embarked on their own unique journeys. Some found themselves at the Energybuild Aberpergwm mine in South Wales, the sole source of high-grade anthracite in Western Europe, while others ended up in a Turkish mine. Both companies approached Baldwin & Francis for assistance in refurbishing these load centres. Encased within 40 cm-thick steel containers capable of withstanding internal arc flashes, these load centres housed critical components. It was a moment of triumph for us to breathe new life into these load centres, guaranteeing an additional 10-15 years of service with our yearly preventative maintenance schedule.

The success story didn’t end there. Our clients, discovering the immense value in refurbishing seemingly obsolete equipment, flooded us with requests for equipment renovation. Even Compass Minerals, the operator of the UK’s oldest salt mine nestled beneath the Cheshire countryside, sought our expertise for a refurbishment project. The benefits were significant for our clients, reducing both time and budget constraints.

On average, the refurbishing of a load centre by our expert team takes just 50% of the time it would require to build one from scratch. Our mining centre of excellence, located in Ayrshire, Scotland, makes this efficiency a reality, allowing clients to access critical equipment that meets the highest-zoned equipment accreditations within a mere two months. This newfound time-saving prowess became a game-changer for major projects, and we are determined to continue this trajectory, bringing these efficiencies to more clients in the future.

Unlocking a World of Expert Solutions

Baldwin & Francis ltd, a pioneering electrical power solutions provider, was founded in 1919 and has earned a well-deserved reputation for delivering tailor-made, world-class solutions. An unrivalled legacy for high-quality specialist switchgear, the capabilities extend far beyond mining, covering the transport, energy, and industrial sectors. Every product we offer is meticulously designed and manufactured in our Sheffield facility, ensuring the highest quality standards every time. As part of the iDESo Group, with headquarters in Sheffield, we are committed to providing exceptional solutions to meet the diverse needs of our clients.

Reach out to our expert team to find out how Baldwin & Francis can assist with your unique requirements.